How AI is Transforming the Product Life Cycle in Discrete Manufacturing

Why Manufacturing Innovation Needs to Get Smaller, Faster, and Smarter

The future of manufacturing isn’t just automated, it’s intelligent, decentralized, and increasingly powered by AI that fits in the palm of your hand. As operational costs rise and global supply chains grow more complex, manufacturers are turning to transformative technologies like small language models (SLMs), AI agents, and trusted data spaces to unlock agility, compliance, and continuous improvement on the shop floor.

According to Gartner’s 2025 Hype Cycle for Discrete Manufacturing, these innovations are rapidly gaining traction, offering strategic advantages to forward-thinking CIOs and plant leaders ready to rethink how people, data, and machines work together.

What Are Small Language Models (SLMs) in Manufacturing?

Small language models are compact AI models designed to run on edge devices with limited compute power. Unlike large, general-purpose models, SLMs are trained on domain-specific datasets like maintenance logs, SOPs, or compliance documentation, making them ideal for real-time, high-impact tasks directly on the factory floor.

Why It Matters

SLMs bring AI capabilities to where data is generated, enabling low-latency processing for use cases such as:

- Predictive maintenance

- Quality inspection

- Compliance documentation

- Voice-activated operator support

This edge-native architecture supports manufacturers’ need for data sovereignty, operational agility, and reduced IT infrastructure costs, all while aligning with sustainability mandates.

The Rise of AI Agents in Smart Manufacturing

AI agents are autonomous software entities capable of perceiving, reasoning, and acting within digital or physical manufacturing environments. Think of them as tireless assistants that monitor, decide, and optimize without constant human input.

Key Use Cases Include:

- Supply chain orchestration

- Asset lifecycle optimization

- Quality control and traceability

- Automated troubleshooting

With built-in awareness of context and goals, AI agents go beyond rule-based automation by adapting to new inputs in real time. They can also collaborate with human workers to close skill gaps and boost productivity in high-complexity environments like automotive or semiconductor manufacturing.

The Foundation: Manufacturing Data Spaces

To scale AI adoption across production networks, manufacturers must solve the data interoperability challenge. That’s where data spaces come in.

What Are Manufacturing Data Spaces?

These are standardized, sovereign, and secure environments for sharing data across internal teams and external partners. They enable better use of digital twins, predictive analytics, and GenAI models by enforcing consistency in data structures and semantics.

Benefits:

- Seamless collaboration across OEMs and suppliers

- Compliance with GDPR and industry regulations

- Enriched AI training data for edge and cloud applications

- Improved visibility across production and supply chain networks

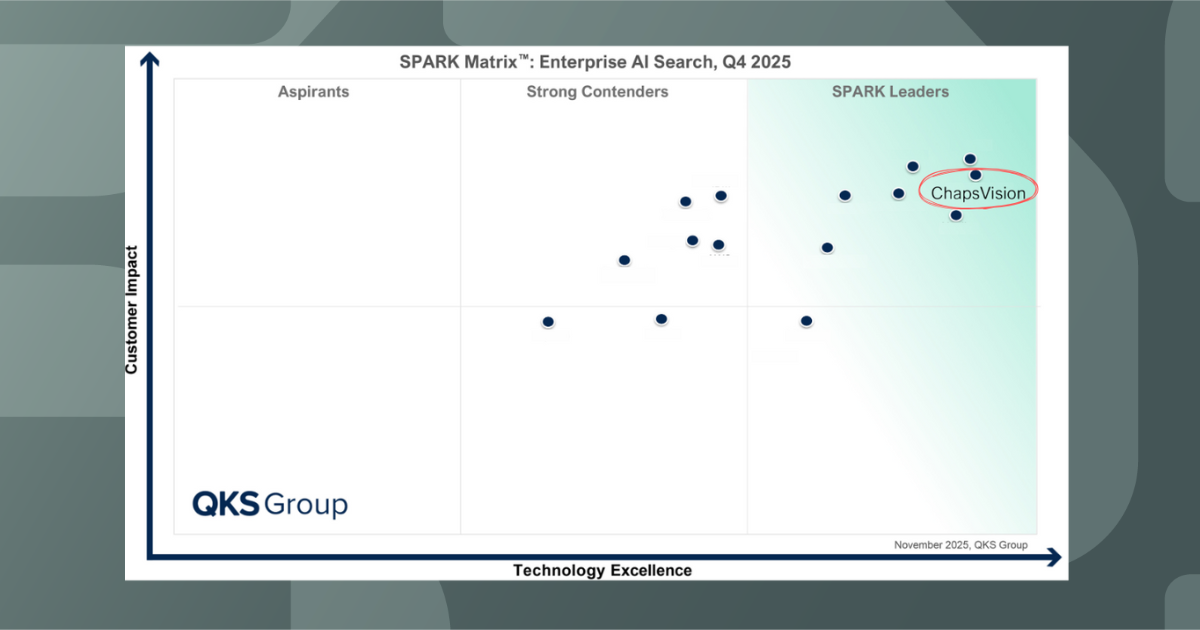

Sinequa’s Role in AI for the Product Life Cycle

Gartner recognizes Sinequa as a key vendor enabling AI throughout the product life cycle. From engineering to end-of-life, manufacturers rely on Sinequa’s AI-powered enterprise search and generative experience platform to unify, structure, and surface data across complex product ecosystems.

Sinequa helps organizations extract actionable insights from siloed sources, like PLM systems, maintenance records, and design documents, accelerating processes such as:

- Generative design and requirements management

- BOM validation and synchronization

- Regulatory compliance and traceability

- Root cause analysis and corrective actions

By combining advanced natural language understanding with scalable indexing and retrieval, Sinequa empowers engineers, quality teams, and product managers to make better, faster, and more informed decisions across every phase of the product life cycle.

What It Means for CIOs and Digital Leaders

The shift toward composable, edge-ready AI is clear. From SLMs that run on shop floor equipment to autonomous AI agents and federated data ecosystems, the manufacturing tech stack is becoming modular, secure, and smarter by design.

To capitalize on these trends, organizations should:

- Start small, scale fast: Pilot SLMs on specific use cases (like predictive maintenance) before expanding.

- Invest in AI-ready data infrastructure: Break down silos with consistent data governance and interoperability frameworks.

- Collaborate across IT and OT: Cross-functional teams are essential to drive successful AI agent adoption.

- Prioritize compliance and transparency: Whether deploying SLMs or machine customers, traceable and explainable AI is critical under EU and global regulations.

Conclusion: The Road Ahead

As discrete manufacturers navigate economic pressure and supply chain volatility, the winners will be those who operationalize AI not just at scale, but with precision. Small language models, AI agents, and trusted data ecosystems offer a practical, secure, and scalable path to digital transformation.

Gartner® Hype Cycle™ for Discrete Manufacturing Technologies, 2025

Get the reportFAQs

SLMs are smaller, more focused AI models optimized for edge use in specific industries. LLMs like GPT-5 are broader and require large infrastructure to operate.

Yes. Their compact size and modular design make them suitable for retrofitting older equipment with modern AI capabilities.

Unlike fixed rule-based systems, AI agents use real-time data and machine learning to make adaptive, context-aware decisions autonomously.

No. Mid-size manufacturers can benefit from industry frameworks (like Manufacturing-X) to standardize data sharing and unlock better AI outcomes. By focusing on smart, interoperable systems, supported by clear governance and business-aligned pilots, manufacturers can boost resilience, compliance, and competitiveness in the age of intelligent production.

Assistant

Assistant